The manufacturing business is growing vertically, either it is an automobile business or an electrical equipment one. And do you know what it requires most to manufacture goods! It is the casting method and, of course, aluminum metal. Have a look at the aluminium die casting companies methodologies.

What is Casting!

Casting is a straightforward, low-cost, and adaptable method of shaping metal into various goods and services. Aluminum casting was used to make anything from energy transmission to automobile engines. Sand castings are used to make the majority of castings, particularly large aluminum goods. Various forms of casting are used to cast metals in different forms as per their nature and usage.

About Die Casting

Die Casting is a pressure-casting method that presses liquid state aluminum into something like a metal die (mold). This manufacturing method is typically utilized in high-volume productions. This casting procedure may generate pretty much exactly cast aluminum pieces that require little processing and refining. This die casting could be called one of the efficient methods of casting various metals into the required structure.

Aluminium Die Casting

Aluminum dies casting companies use lighter and dimensionally stable compositions, ideal for complicated component designs and slim partitions. Aluminum is an excellent metal for die casting because it has excellent oxidation tolerance and tensile qualities, along with exceptional heat and electric conduction. The die casting business relies on low-density aluminum materials. The Aluminum Die Casting technique preserves its durability at extremely intense degrees; cold tank equipment is required.

More About Aluminium Die Casting

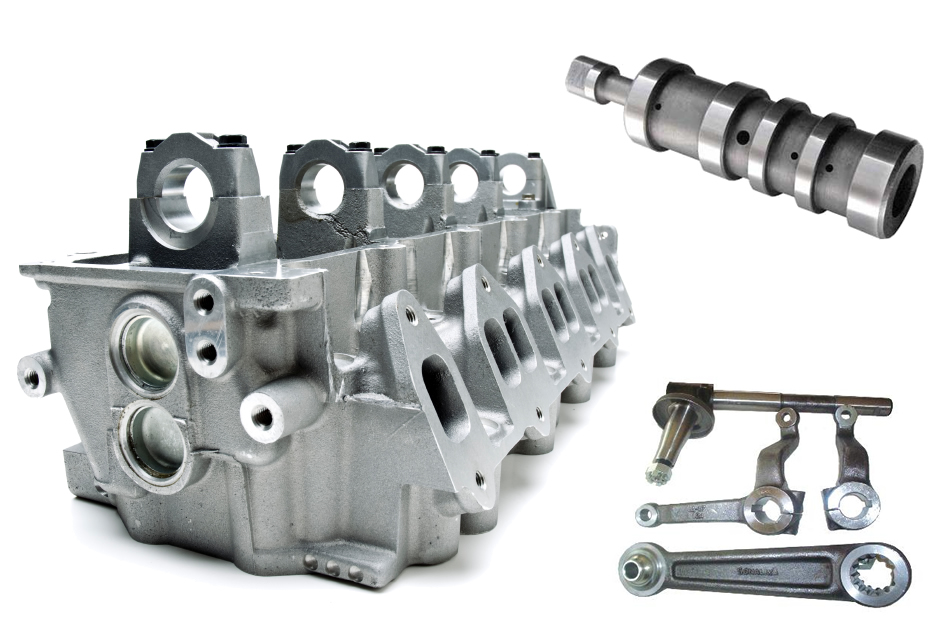

Aluminum dies casting is an industrial method in which metal (specifically aluminum or its alloys) is molted at intense force to manufacture custom-shaped, specified, seamless, and toned-exterior components. The heated room or cold room die casting processes can be used to complete this operation. The cold chamber casting process is relatively popular due to aluminum’s high thermal conductivity of 620 – 630 degrees Celsius.

The aluminium die casting companies method is simple since it uses a steel mold to quickly manufacture huge volumes of castings. High-pressure procedures are used to moltaluminum initially. The casting process subsequently commences using die casting presses compressing both die sides altogether, accompanied by the introduction of molten aluminum metal or its alloy inside the die chamber. The design is produced after it hardens, and the die sides are brought apart to allow the mold to be removed.

The whole manufacturing process of aluminum die-casting companies is great for producing different shapes and goods used in automobiles and electronics.