In the intricate realm of medical gadgets, the decision of a reliable and reputable medical wire manufacturer is a critical choice that directly impacts the quality, safety, and performance of healthcare items. Whether utilized in surgical strategies, diagnostic gear, or implantable gadgets, medical wires play a pivotal job in the healthcare biological system.

Regulatory Compliance and Certifications:

One of the premier considerations is the manufacturer’s adherence to regulatory standards and certifications. Guarantee that the manufacturer conforms to industry-explicit regulations, for example, ISO 13485 (Medical Gadgets), and that their items meet the necessary quality and safety necessities. Search for certifications from relevant authorities, indicating a promise to maintain the best expectations in medical manufacturing.

Material Selection and Biocompatibility:

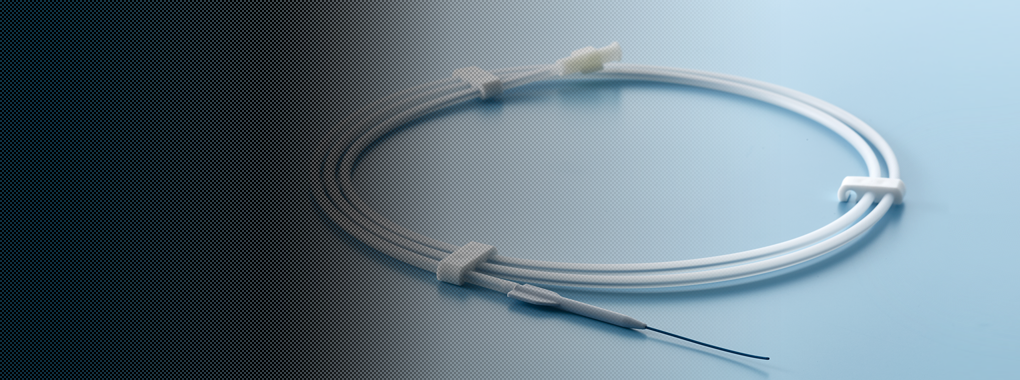

Medical wires come into direct contact with the human body in various applications. The selection of biocompatible materials is crucial to avoiding adverse reactions. A reputable manufacturer carefully picks materials that are safe for use within the body as well as display the necessary mechanical properties for the intended application.

Precision in Manufacturing Processes:

Precision is paramount in the medical industry, and the manufacturing processes utilized by the medical wire manufacturer should mirror this obligation to accuracy. From wire drawing to coating and assembly, each step of the manufacturing system should be executed with fastidious precision to guarantee consistency, reliability, and adherence to determined tolerances.

Customization Capabilities:

Medical applications can vary generally, and a manufacturer’s ability to offer redesigned arrangements is a significant factor. Consider a manufacturer that can tailor medical wires to explicit aspects, configurations, and materials based on the exceptional prerequisites of your medical gadget or application. Customization guarantees that the medical wires seamlessly integrate into your item.

Quality Control and Testing Protocols:

Thorough quality control measures and testing protocols are indicative of a manufacturer’s obligation to deliver reliable medical wires. Inquire about the testing techniques utilized, including dimensional checks, elasticity testing, and surface finish inspections. A transparent approach to quality control demonstrates a dedication to producing reliably excellent items.

Industry experience and reputation:

Consider the manufacturer’s industry experience and reputation. A manufacturer with a demonstrated track record in the medical field is bound to understand the extraordinary challenges and prerequisites of medical wire manufacturing. Search for testimonials, case reviews, or references that feature effective collaborations with other healthcare organizations.

Scalability and Production Capacity:

Assess the manufacturer’s scalability and production capacity to meet your current and future requirements. A manufacturer with the ability to scale production volumes while maintaining quality is crucial, especially in the event that your medical gadget goes through market expansion or experiences increased demand.

Supply Chain Resilience:

The resilience and stability of the manufacturer’s supply chain are essential considerations. Confirm that the manufacturer sources materials from reputable providers and has contingency plans in place to mitigate potential disturbances. A reliable supply chain adds to the steady availability of medical wires for your applications.

Selecting a manufacturer requires a careful evaluation of various factors to guarantee that the chosen partner aligns with your quality, safety, and compliance prerequisites. You can make an informed choice that upholds the achievement and reliability of your medical gadgets.